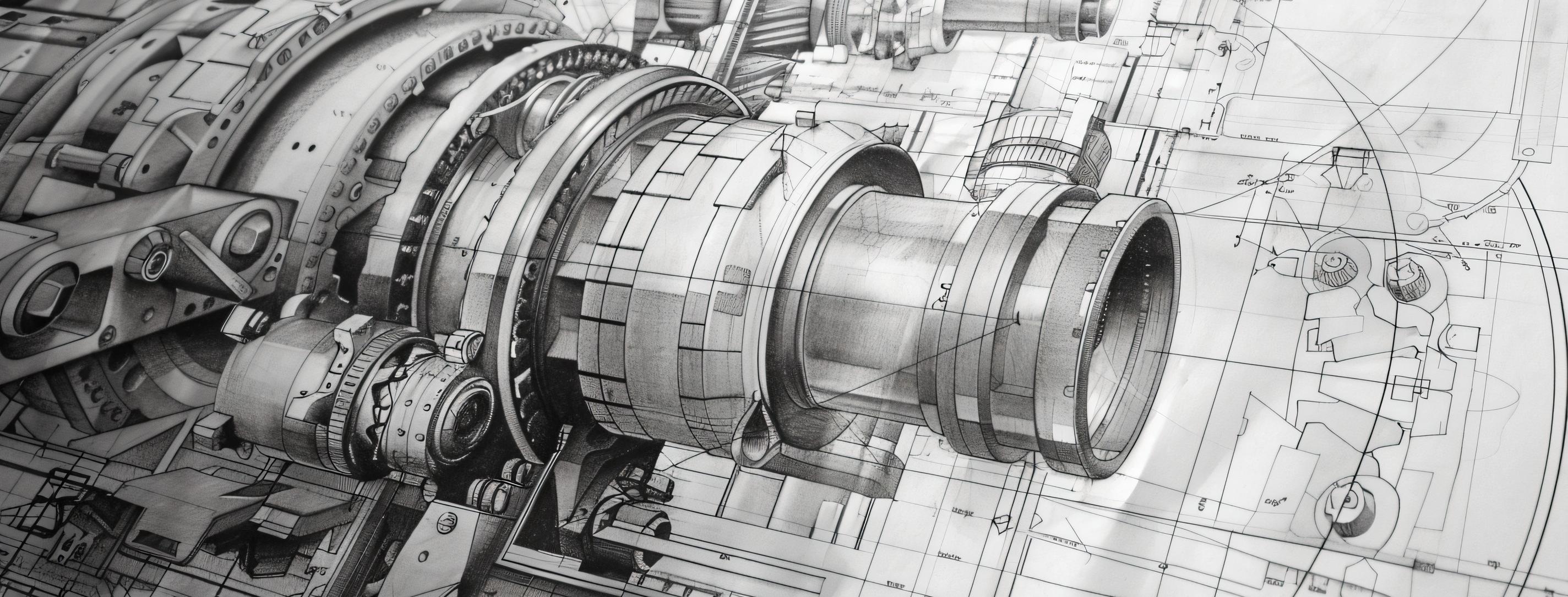

The Spherical Bronze Socket Liner of Cone Crushers: A Vital Component in Crushing Efficiency

In the realm of mineral processing and aggregate production, cone crushers are indispensable machines designed to reduce large rocks into smaller, manageable fragments. Central to their operation is the spherical bronze socket liner, a component critical spare part for ensuring smooth mechanical function and durability. This essay explores the design, material properties, and operational significance of this often-overlooked spare part.

Function and Design

The spherical bronze socket liner resides within the cone crusher's eccentric assembly, serving as a bearing surface spare part that facilitates the gyratory motion of the main shaft. As the mantle rotates, this spare part accommodates multi-directional movement, allowing the cone crushers head to oscillate in a controlled path. This spare part's spherical geometry is engineered to distribute stress evenly across the component, mitigating localized wear and compensating for minor misalignments during operation. This design not only enhances mechanical stability but also prolongs the lifespan of adjacent components by reducing uneven load distribution for cone crushers.

Material Advantages

Bronze of this spare part, an alloy primarily of copper and tin, is chosen for its exceptional wear resistance, self-lubricating properties, and ability to withstand high-impact loads. The addition of elements like lead further enhances its anti-frictional qualities, minimizing heat generation and reducing the need for external lubrication. Bronze’s corrosion resistance is particularly advantageous in harsh environments, where exposure to moisture and abrasive particles is common. These attributes make bronze an ideal material for of the spherical bronze socket liner, ensuring reliable performance under continuous operational stress of this spare part.

Operational Benefits

The integration of this spare part directly impacts cone crushers' efficiency. By enabling smooth gyration, the spherical bronze socket liner optimizes energy transfer, leading to consistent particle size reduction and higher throughput. This spare part's durability reduces maintenance frequency of cone crushers, lowering operational downtime of cone crushers and replacement costs of cone crushers. Furthermore, the spherical bronze socket liner’s ability to absorb vibrations contributes to quieter and more stable machine operation, enhancing workplace safety.

Maintenance Considerations

Though designed for longevity, periodic inspection of this spare part is essential. Wear patterns can indicate alignment issues, prompting timely adjustments. Replacement involves disassembling the eccentric, underscoring the need for quality components to avoid recurrent interventions.

Conclusion

This spare part is a cornerstone of cone crushers functionality, harmonizing robust material properties with intelligent design. Its role in facilitating efficient crushing, reducing wear, and ensuring operational continuity underscores its value in industrial applications. As industries demand higher efficiency and reliability, the innovation and maintenance of such components remain pivotal to advancing crushing technology of cone crushers.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/