The Critical Roles of the Main Shaft and Transmission Shaft in Cone Crushers

Cone crushers are indispensable in mining and construction for reducing large rocks into smaller, usable aggregates. At the heart of their functionality lie two pivotal components: the main shaft and the transmission shaft. The main shaft and the transmission shaft synergize to ensure efficient crushing operations, directly influencing productivity, durability, and safety.

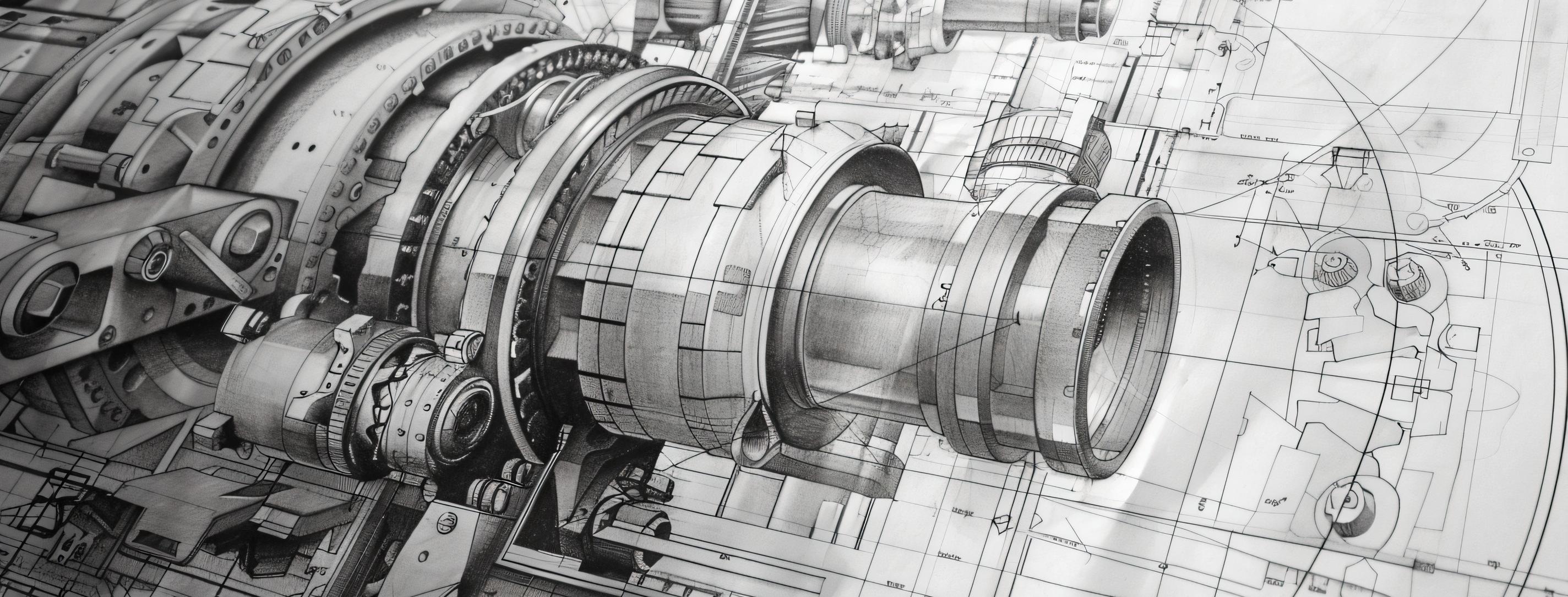

Main Shaft: Structural Backbone and Crushing Force

The main shaft is the cone crushers' central structural element, supporting the mantle—the component responsible for compressing rocks against the stationary concave. Crafted from high-strength steel alloys, the main shaft withstands immense mechanical stress, abrasion, and thermal fluctuations during the operation of cone crushers. The main shaft robust design ensures the mantle’s precise gyratory motion, generating the necessary compressive force to fragment materials. The main shaft’s alignment and integrity are crucial; even minor deviations can reduce the crushing efficiency or the cause uneven wear of cone crushers. Additionally, the main shaft’s configuration allows adjustments to the crushing gap of the cone crushers, enabling control over the output size—a vital feature for meeting diverse product specifications. A failure here in cone crushers could halt operations, incurring costly downtime and safety risks from potential component disintegration.

Transmission Shaft: Power Delivery and Operational Efficiency

The transmission shaft bridges the motor’s power to the main shaft, converting electrical energy into mechanical force of cone crushers. Engineered to handle high torque and rotational speeds, the transmission shaft ensures seamless energy transfer, minimizing losses that could escalate operational costs. Precision bearings and alignment are critical to prevent vibrations or premature wear of cone crushers, which might disrupt performance. Efficient power transmission of the transmission shaft not only optimizes energy use but also maintains consistent crushing rhythms, essential for uniform product quality of cone crushers. Regular lubrication and alignment checks are imperative to sustain its function, underscoring the need for diligent maintenance practices.

Synergy and Conclusion

The interplay between the main shaft and the transmission shaft is fundamental. The transmission shaft’s effective energy transfer empowers the main shaft to execute forceful, precise gyrations, translating raw power into productive crushing. Together, they enhance machine reliability, reduce energy consumption, and mitigate safety hazards. Advances in metallurgy and engineering continue to refine these components of cone crushers, extending service life and operational efficiency.

In industries where downtime translates to significant financial loss, the reliability of the main shaft and the transmission shaft underpins continuous productivity. Thus, the main shaft and the transmission shaft's meticulous design and maintenance are not merely technical necessities but cornerstones of industrial progress.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/