The Importance of the Main Shaft Cone Assembly in the CH870 Single Cylinder Cone Crusher

The CH870 Single Cylinder Cone Crusher is a pivotal machine in mining and aggregate industries, designed to crush hard rocks into precise, uniform sizes. At the heart of the CH870 Single Cylinder Cone Crusher's operational efficiency lies the main shaft cone assembly—a component critical to the crusher’s performance, durability, and reliability. This essay explores the significance of this assembly, emphasizing its role in ensuring productivity, safety, and cost-effectiveness.

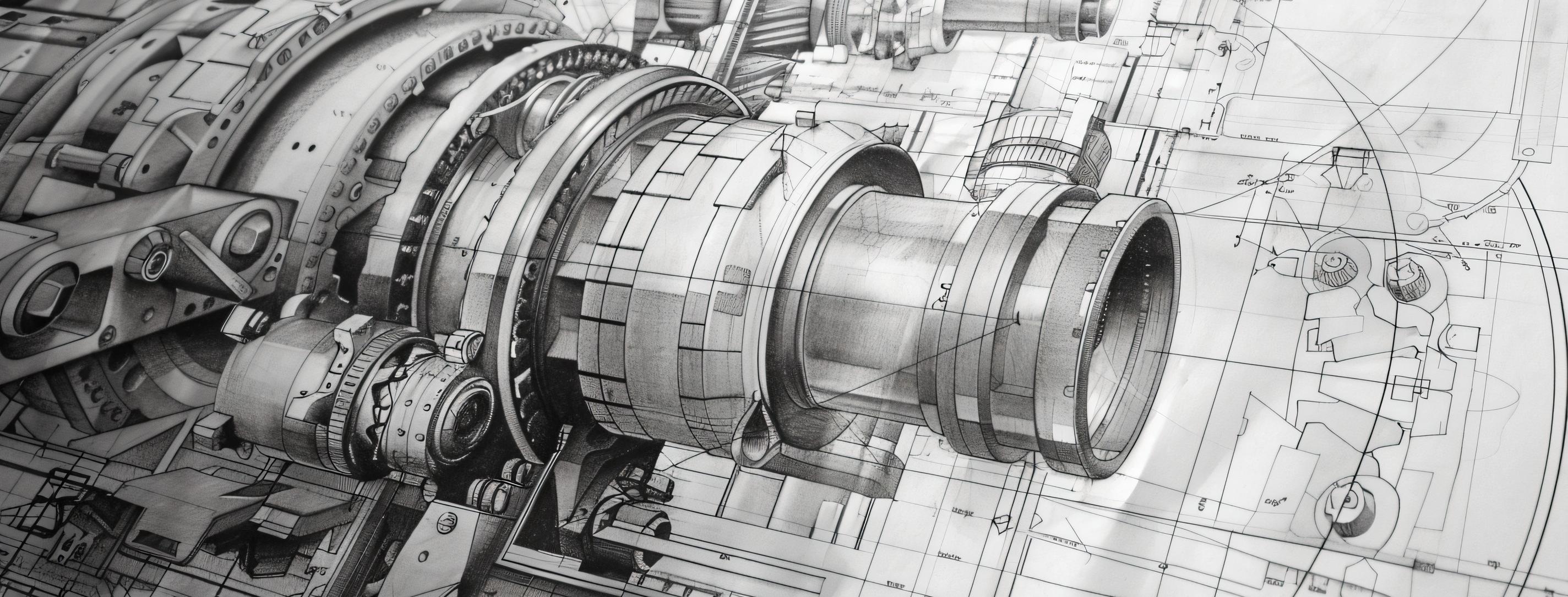

Structural and Functional Core

The main shaft cone assembly serves as the CH870 Single Cylinder Cone Crusher’s backbone, integrating components like the main shaft, mantle, and eccentric bushing. It transmits rotational force from the motor to the crushing chamber, enabling the mantle to compress rocks against the concave. The single-cylinder hydraulic system of this cone crusher, unique to the CH870, relies on the main shaft cone assembly’s vertical movement to adjust the closed-side setting (CSS), directly influencing output size. Precise control over CSS ensures consistent particle distribution, vital for meeting product specifications in applications such as construction or ore processing.

Load-Bearing and Durability

In high-stress environments, the main shaft cone assembly withstands immense mechanical forces. Constructed from high-strength, heat-treated steel, it resists wear, deformation, and fatigue. A robust main shaft cone assembly minimizes downtime caused by fractures or misalignment, which could halt operations and incur repair costs. For instance, in a mining scenario, unplanned stoppages disrupt supply chains, making the shaft’s resilience a cornerstone of operational continuity.

Power Transmission and Efficiency

The main shaft cone assembly’s efficiency in transferring power dictates the crusher’s energy consumption and throughput. Optimal alignment reduces friction and vibration, enhancing energy efficiency. This translates to lower operational costs per ton of processed material—a key metric in resource-intensive industries. Additionally, the hydraulic adjustment mechanism allows real-time CSS modifications, maintaining the performance of the cone crusher even as wear occurs, thereby prolonging component lifespan.

Maintenance and Safety

A well-engineered mmain shaft cone assembly simplifies maintenance. Modular designs enable swift replacement of worn parts, reducing service time. Moreover, its reliability mitigates risks of catastrophic failures, safeguarding personnel from hazards associated with sudden mechanical breakdowns.

Conclusion

The main shaft cone assembly is indispensable to the CH870 Single Cylinder Cone Crusher’s functionality. Its structural integrity, power transmission efficiency, and adaptability underpin the crusher’s ability to deliver high-quality output sustainably. By ensuring durability and operational safety, this assembly not only enhances productivity but also supports the economic viability of industries reliant on crushing technology. In essence, it is the linchpin that transforms raw rock into valuable resources.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/