The Importance of Non-Destructive Testing on the Main Shaft of SP Multi Cylinder Hydraulic Cone Crusher

The multi cylinder hydraulic cone crusher is a cornerstone of modern mineral processing and aggregate production, renowned for its efficiency and reliability in crushing hard materials. At the heart of this machinery lies the main shaft, a critical component responsible for transmitting power, supporting crushing forces, and ensuring operational stability. To maintain the integrity and longevity of the main shaft, non-destructive testing (NDT) has emerged as an indispensable practice. This article explores why NDT is vital for safeguarding the main shaft in SP multi-cylinder hydraulic cone crushers, ensuring optimal performance and minimizing downtime.

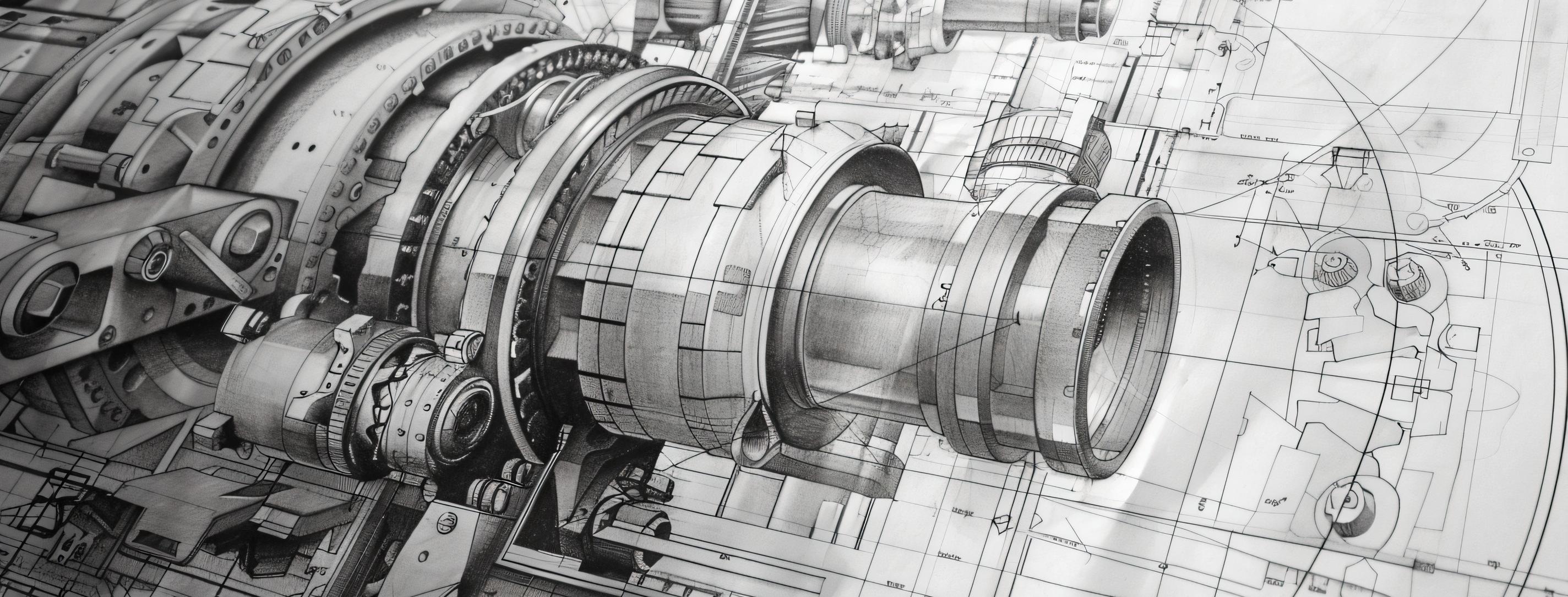

Role of the Main Shaft in Multi-Cylinder Hydraulic Cone Crushers

The main shaft in a multi-cylinder hydraulic cone crusher acts as the central axis, connecting the crushing head to the eccentric assembly. It endures immense torsional and compressive stresses during operation, making it prone to wear, micro-cracks, or structural fatigue over time. A failure in the main shaft can lead to catastrophic breakdowns, costly repairs, and prolonged production halts. For SP multi-cylinder hydraulic cone crushers, which prioritize precision and durability, proactive monitoring of the main shaft is non-negotiable.

Why Non-Destructive Testing Matters

NDT techniques such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing enable engineers to evaluate the main shaft without disassembling the multi-cylinder hydraulic cone crusher or compromising its functionality. These methods detect subsurface flaws, surface cracks, or material inconsistencies that are invisible during routine visual inspections. For instance, ultrasonic waves can identify internal defects in the main shaft, while magnetic particle testing highlights surface-level discontinuities. By identifying issues early, NDT prevents unexpected failures and extends the service life of both the main shaft and the multi-cylinder hydraulic cone crusher.

Enhancing Safety and Operational Efficiency

In SP multi cylinder hydraulic cone crushers, the main shaft operates under extreme loads and high-speed conditions. Any undetected flaw in this component can escalate into a safety hazard, risking equipment damage and operator safety. NDT mitigates these risks by providing a comprehensive assessment of the main shaft’s structural health. Regular testing ensures compliance with safety standards and reduces the likelihood of unplanned shutdowns. Moreover, a well-maintained main shaft enhances the crushing efficiency of the multi cylinder hydraulic cone crusher, ensuring consistent output quality and energy efficiency.

Cost Savings and Sustainability

Implementing NDT on the main shaft of a multi-cylinder hydraulic cone crusher aligns with sustainable operational practices. Early defect detection minimizes material waste by avoiding premature component replacements. It also reduces energy consumption by maintaining optimal alignment and balance in the main shaft, which directly impacts the crusher’s performance. For industries relying on SP multi cylinder hydraulic cone crushers, integrating NDT into maintenance schedules translates to long-term cost savings and a smaller environmental footprint.

The main shaft is the backbone of SP multi-cylinder hydraulic cone crushers, and its reliability directly influences productivity and profitability. Non-destructive testing serves as a proactive safeguard, ensuring this critical component remains free from defects that could compromise performance. By adopting advanced NDT methodologies, operators of multi cylinder hydraulic cone crushers can achieve unparalleled operational resilience, safety, and cost efficiency. In an industry where downtime is synonymous with lost revenue, investing in the health of the main shaft through NDT is not just a best practice—it’s a strategic imperative.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/