The Advantages of the SP300 Multi-Cylinder Hydraulic Cone Crusher

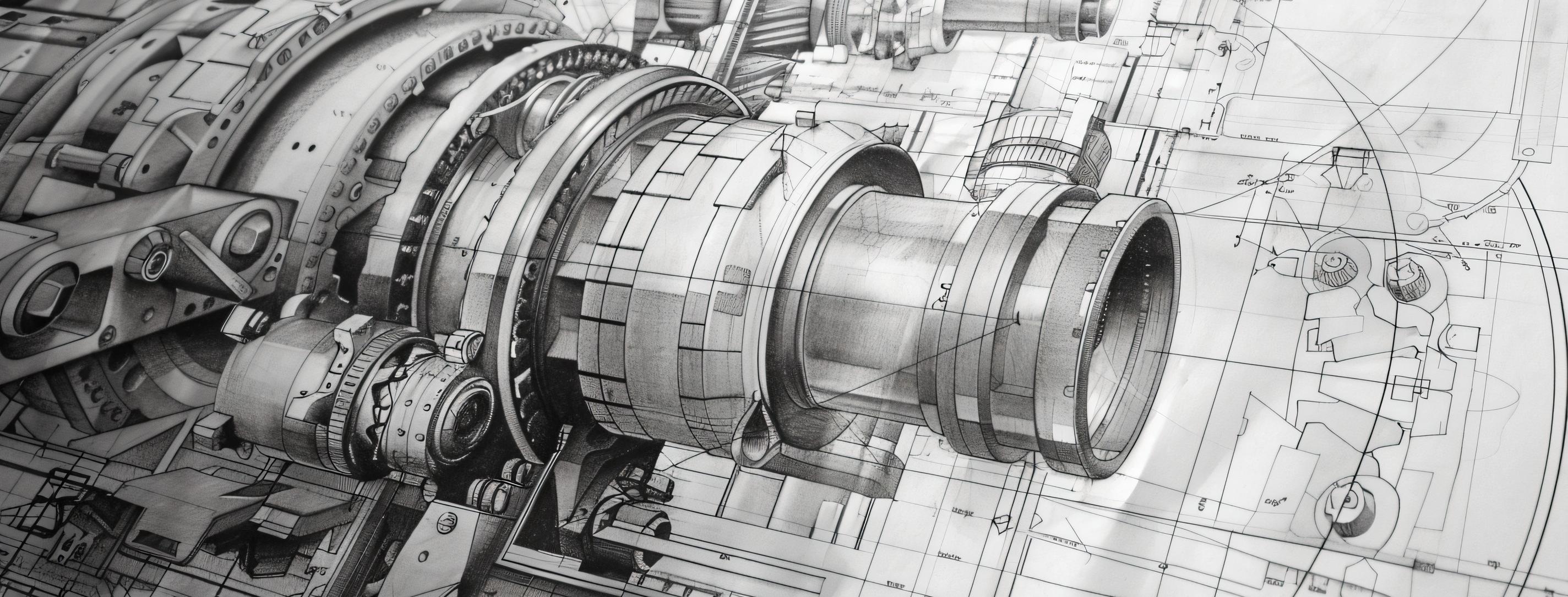

The SP300 Multi-Cylinder Hydraulic Cone Crusher represents a significant advancement in crushing technology, offering a range of advantages that enhance productivity, efficiency, and operational flexibility in industries such as mining, construction, and aggregate processing. With SP300 Multi-Cylinder Hydraulic Cone Crusher's innovative design and advanced hydraulic systems, the SP300 Multi-Cylinder Hydraulic Cone Crusher addresses critical challenges in material processing, making it a preferred choice for modern operations.

1. Superior Crushing Efficiency and Performance

The SP300 cone crusher’s multi-cylinder hydraulic system ensures exceptional crushing force and stability. Unlike single-cylinder crushers, the multi-cylinder configuration distributes power evenly across the crushing chamber, enabling consistent particle size reduction and improved product shape. This results in higher yields of uniformly sized materials, which are essential for high-quality concrete, asphalt, and road base applications. Additionally, the hydraulic adjustment mechanism allows operators to modify the discharge settings quickly and precisely, optimizing output for varying material types and project requirements.

2. Energy Efficiency and Cost Savings

Energy consumption is a major concern in crushing operations. The SP300 cone crusher incorporates an intelligent hydraulic system that minimizes energy waste by adjusting the cone crusher’s power based on real-time load conditions. This not only reduces electricity usage but also lowers operational costs. Furthermore, the cone crusher’s durable components and robust design reduce downtime and maintenance expenses, contributing to long-term economic benefits.

3. Enhanced Automation and Safety

The SP300 cone crusher is equipped with advanced automation features, including real-time monitoring and remote control capabilities. Sensors detect parameters such as temperature, pressure, and feed levels, enabling proactive adjustments to prevent overloads or mechanical failures. Automated safety mechanisms, such as the hydraulic clearing system, protect the crusher from damage caused by uncrushable materials. These features enhance operational safety, reduce human error, and ensure uninterrupted production.

4. Versatility Across Applications

The SP300 cone crusher’s adaptability makes it suitable for processing a wide range of materials, from hard granite to medium-hard ores. Its adjustable crushing chamber and multiple cavity options allow operators to switch between fine and coarse crushing modes effortlessly. This versatility eliminates the need for multiple machines, saving space and capital investment while meeting diverse project demands.

Conclusion

The SP300 Multi-Cylinder Hydraulic Cone Crusher stands out as a technologically advanced solution that combines efficiency, reliability, and adaptability. By improving crushing performance, reducing energy costs, and integrating smart automation, it empowers industries to achieve higher productivity and sustainability. For businesses seeking to optimize their material processing workflows, the SP300 offers a competitive edge in an increasingly demanding market.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/