The Advantages of the HP300 Multi-Cylinder Hydraulic Cone Crusher

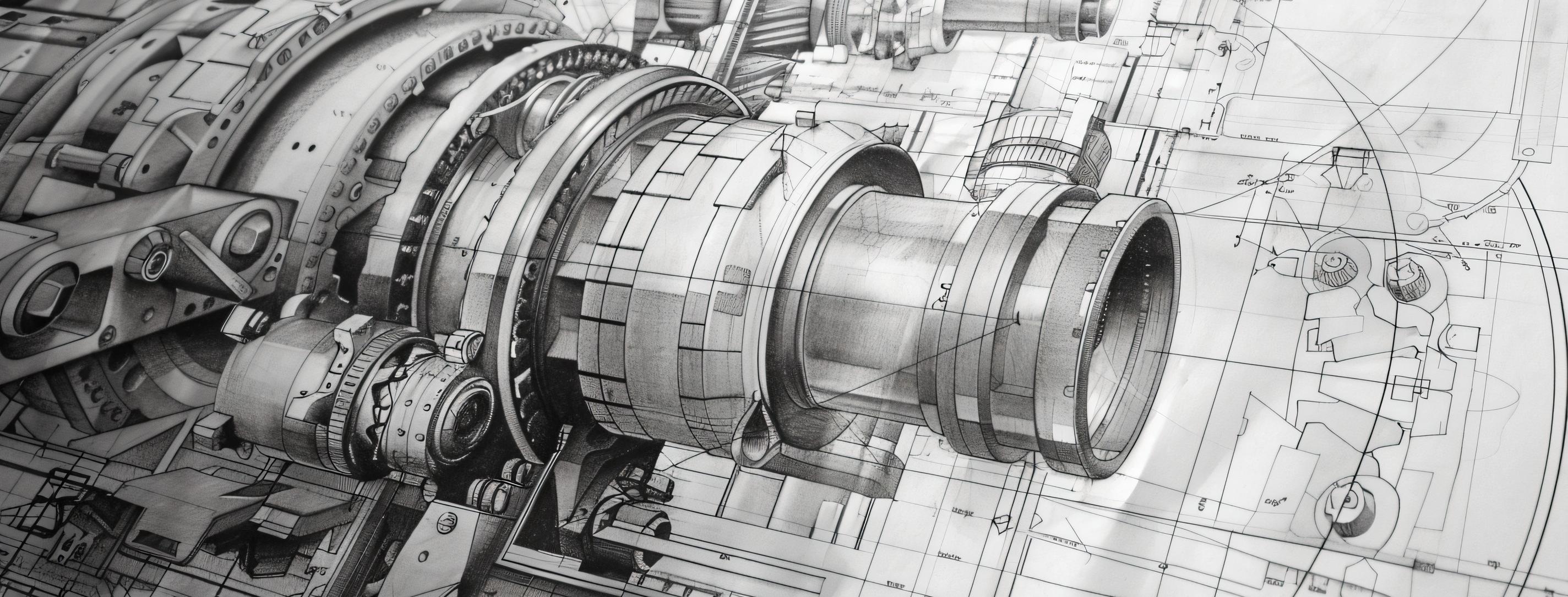

In the mining and aggregate industries, efficient material processing is paramount. The HP300 Multi-Cylinder Hydraulic Cone Crusher stands out as a technological advancement, offering numerous advantages that enhance productivity, safety, and operational flexibility. This essay explores its key benefits.

1. Enhanced Efficiency and Productivity

The HP300’s multi-cylinder hydraulic system of HP300 Multi-Cylinder Hydraulic Cone Crusher generates a higher crushing force compared to traditional crushers. This allows it to process hard materials like granite and iron ore with remarkable speed, significantly boosting throughput. Its optimized crushing chamber design ensures consistent output, reducing the need for re-processing and maximizing productivity in high-demand operations.

2. Precision and Safety with Hydraulic Control

Equipped with an advanced hydraulic system, the HP300 Multi-Cylinder Hydraulic Cone Crusher enables real-time adjustment of the discharge opening without stopping the machine. This feature not only saves time but also enhances safety by minimizing manual intervention. The hydraulic overload protection mechanism automatically releases uncrushable materials, preventing mechanical failures and downtime caused by blockages or excessive loads.

3. Superior Particle Shape and Uniformity

The HP300 Multi-Cylinder Hydraulic Cone Crusher’s interparticle crushing action, facilitated by its multi-cylinder design, produces uniformly shaped aggregates. This results in high-quality end products crucial for construction applications, where well-graded materials improve structural integrity. Such consistency reduces waste and meets stringent industry standards, enhancing customer satisfaction.

4. Energy Efficiency and Environmental Benefits

Despite its power, the HP300 cone crusher operates with notable energy efficiency. Its hydraulic system optimizes power consumption by adjusting the crushing force based on material hardness, reducing unnecessary energy use. Lower noise levels and reduced dust emissions further contribute to environmentally friendly operations, aligning with sustainability goals.

5. Automation and Ease of Maintenance

Integration with modern automation systems allows remote monitoring and control, enabling operators to optimize performance in real time. Additionally, the HP300 cone crusher’s design prioritizes accessibility for maintenance. Critical components are easily reachable, and the hydraulic lubrication system minimizes wear, extending the machine’s lifespan and reducing downtime.

6. Versatility Across Applications

The HP300 cone crusher excels in diverse settings, from mining to recycling. Its adjustable settings accommodate various materials, including abrasive ores and softer aggregates, making it a versatile solution for dynamic operational needs.

Conclusion

The HP300 Multi-Cylinder Hydraulic Cone Crusher represents a leap forward in crushing technology. By combining power, precision, and adaptability, it delivers higher efficiency, superior product quality, and reduced operational costs. For industries prioritizing performance and sustainability, the HP300 cone crusher is an invaluable asset, driving productivity while minimizing environmental impact.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/