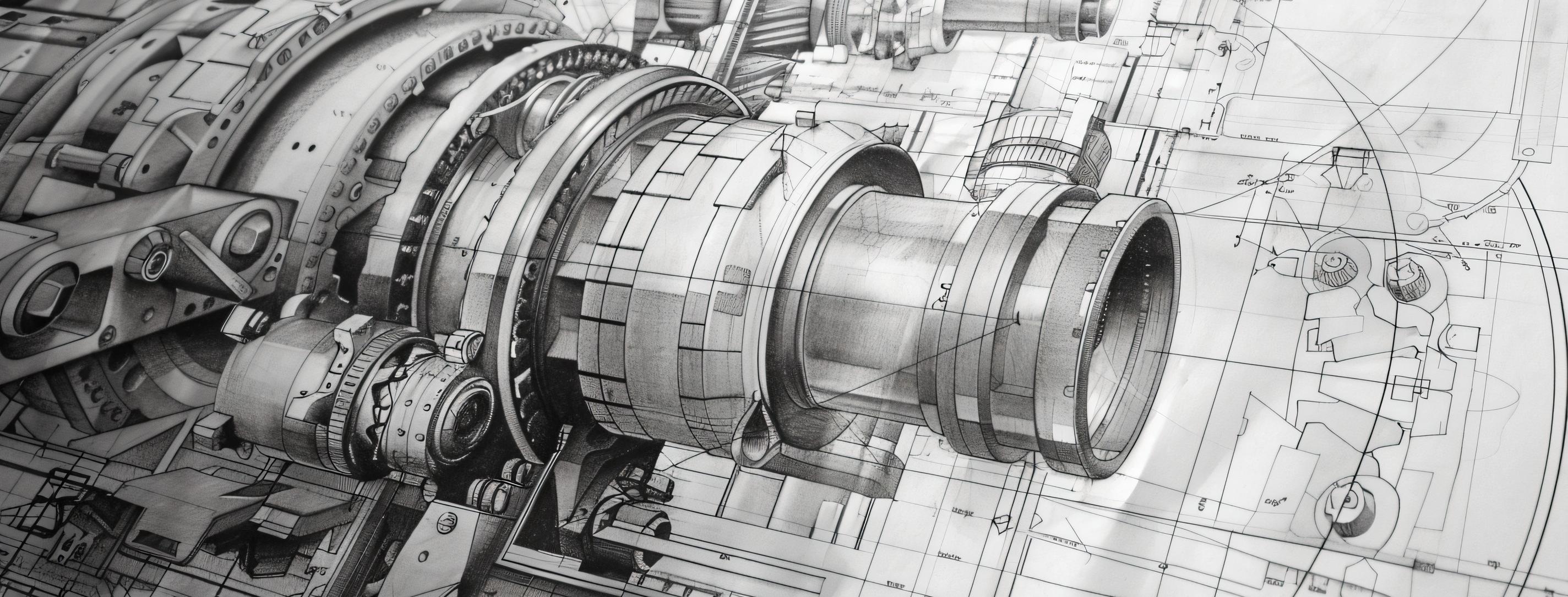

Shanghai Zhuyan_Main Frame of Symons 4 FT Cone Crusher

Introduction to the advantages

As the core load-bearing structure of the Symons 4 FT Cone Crusher, the main frame components of

the 4FT Symons cone crusher, with excellent design and advanced technology, have become the

key guarantee for the efficient and stable operation of the equipment. The main frame of Symons

4FT Cone Crusher advantages are mainly reflected in the following four aspects:

1、 High strength structural design, stable and reliable

The main frame of Symons 4FT Cone Crusher is made of high-strength alloy steel cast/welded as a whole, combined with a box shaped main frame and internal reinforcement rib layout, effectively dispersing the impact load and vibration stress generated during crushing operations. Through finite element analysis optimization, the structural deformation of the main frame resistance has been improved by more than 30% of other main frames, ensuring stable geometric accuracy under long-term heavy load conditions and extending the service life of the entire machine.

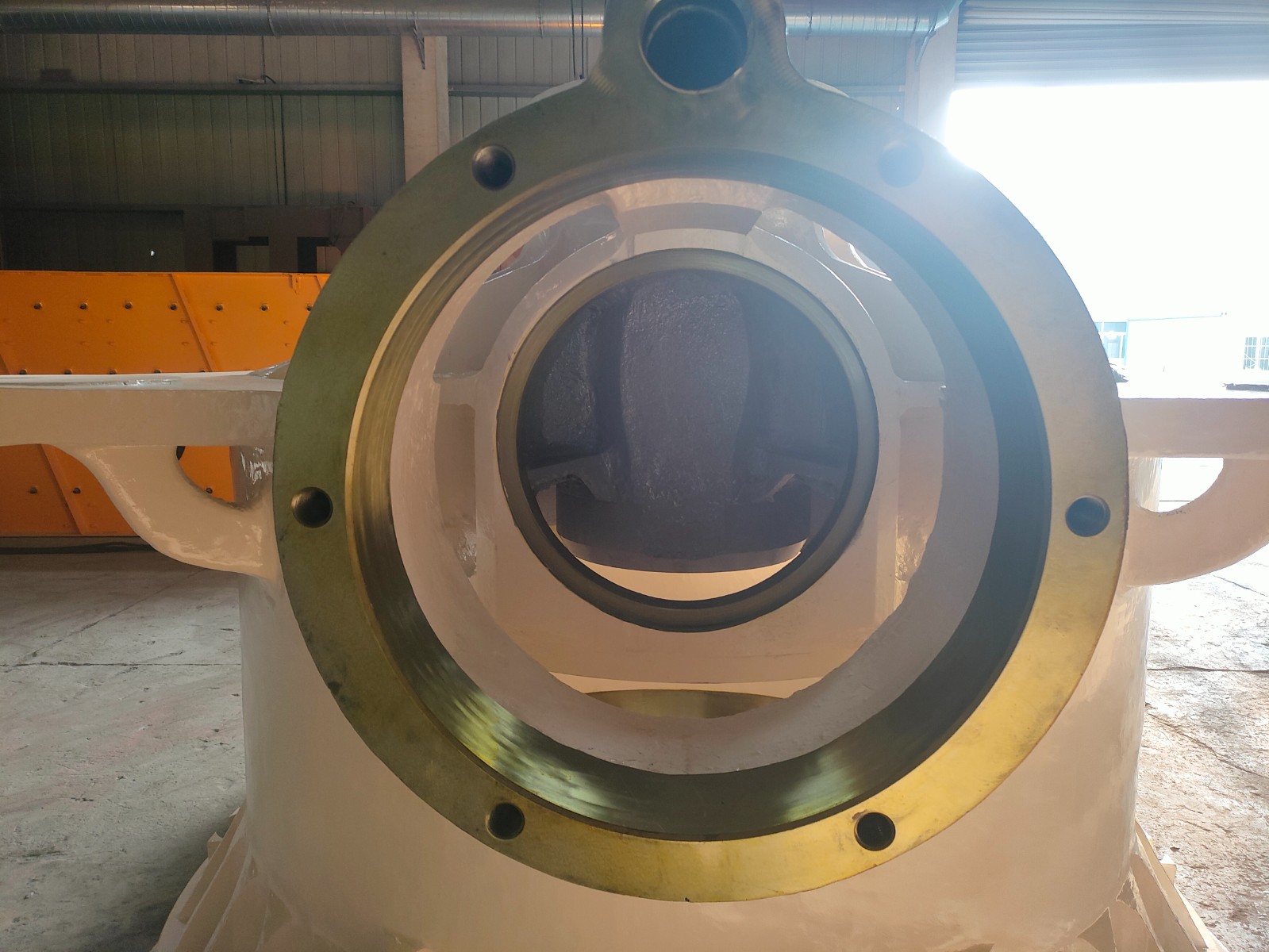

2、 Precision machining technology, excellent adaptability

The key mating surfaces of the main frames are precision machined by CNC machine tools, and the flatness error of the bearing seat installation surface is ≤ 0.05mm. The fitting tolerance of the main frame between the dynamic cone assembly and the eccentric sleeve is strictly controlled within the ISO H7/g6 standard. Modular design of the main frame supports quick replacement of lining plates and worn parts, reserves standardized maintenance windows, improves maintenance efficiency by 40%, and significantly reduces downtime costs of the Symons 4FT cone crusher.

3、 Innovative dust sealing system

Integrated multi-level labyrinth seal and air pressure balancing device of the Symons 4FT Cone Crusher, combined with high elasticity rubber sealing ring, forms a three-dimensional dust barrier. Laboratory tests have shown that this design of Main Frame of 4FT Symons Cone Crusher can block more than 99.5% of dust from entering the lubrication system, extending the service life of bearings to 8000 hours, and is particularly suitable for high dust mining environments.

4、 Intelligent upgrade compatible architecture

The host rack reserves sensor interfaces and installation positions for data transmission modules, supporting seamless integration with intelligent operation and maintenance systems of the Symons 4FT cone crusher such as vibration monitoring and temperature sensing. The structural reinforcement design is compatible with a 20% capacity increase space in the future, providing a hardware foundation for the intelligent and large-scale upgrading of 4FT Symons Cone Crusher.

This main frame of 4FT Symons Cone Crusher has passed ISO 9001 quality system certification and its reliability has been verified in over 300 mining projects worldwide. The average time between failures is 18000 hours, and the comprehensive operation and maintenance cost is reduced by 25% compared to similar products. It is an ideal choice for medium-sized crushing lines.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/